Past Research

The innovative research at the FML over the last years, which combines materials with specific functions, has laid the foundation of numerous FML spin-off companies. Here, we present a summary of our past research and companies thereof.

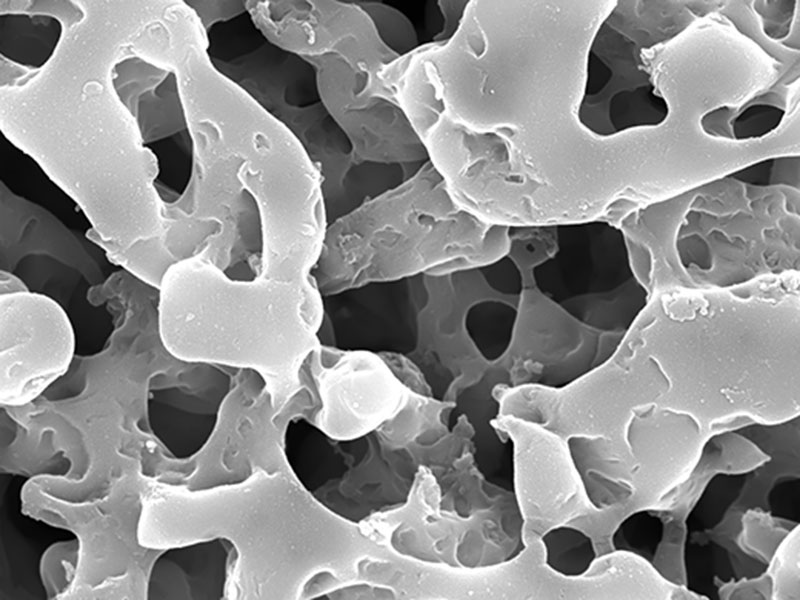

We have developed a scalable approach towards large scale fabrication of porous polymeric membranes based on a two-step procedure, which exploits soluble template nano-particles allowing the formation of porous polymeric systems.

This novel technology allows industrial application in various areas leading to three FML-spinoffs:

Nanoparticle Chemistry

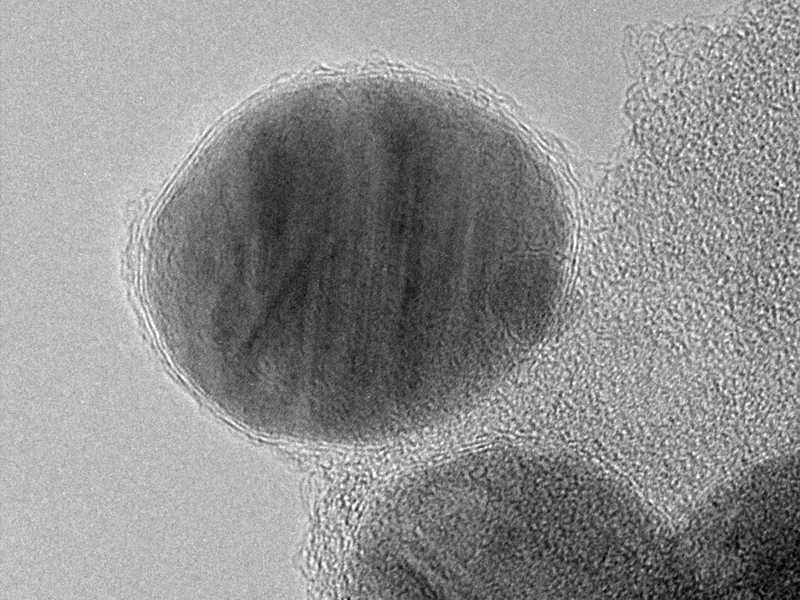

We have developed highly magnetic carbon coated metal nanoparticles that can act as semi-heterogeneous support for protecting groups, reagents, transition metal complexes or organocatalysts. Compounds covalently attached to the graphene coating are amenable to rapid separation from the reaction mixture with the aid of an external magnet.

FML-spinoffs:

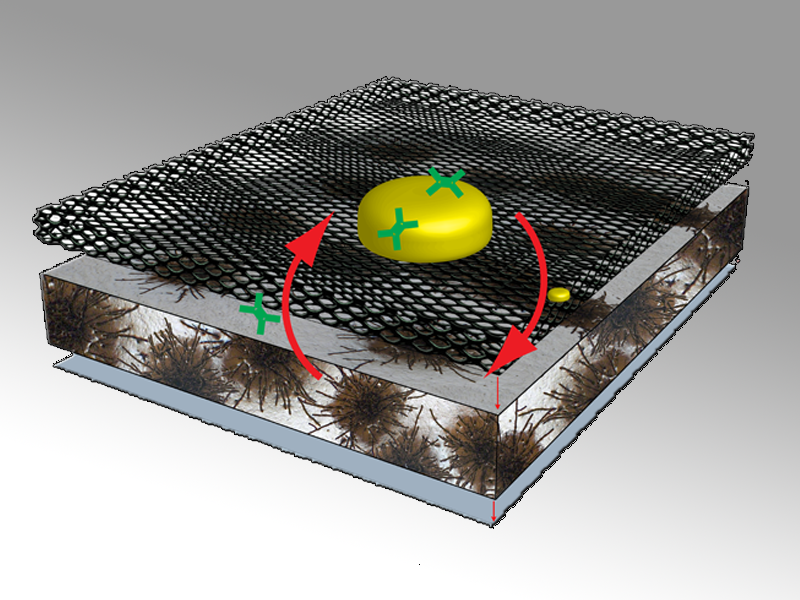

Ancient DNA is preserved in fossils for over thousands to millions of years. This natural way of DNA preservation inspired our encapsulation of DNA into glass particles. Within the particles, the DNA is hermetically sealed and protected from severe environmental attack, such as from reactive oxygen spieces and high temperatures. Various applications from anti-counterfeit tagging to analytical sensors and data storage are currently under investigation.

FML-spinoff:

Multifunctionality is a strong demand set to the next generation of materials. One way to cope with this trend is the use of biological materials and systems. The result from this research are biomaterials and living materials, which find their way into todays dental materials, sensor technolgy or textile production.

FML-spinoff:

Soft Materials

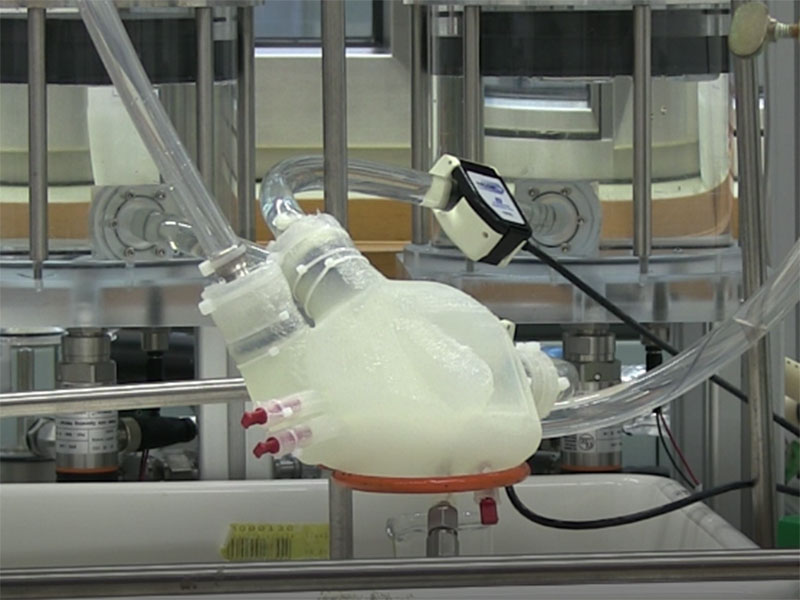

3D printing technology enables the production of lost-wax casted soft silicone pumps, which are driven by combustion and can be used to build soft motors (e.g., an artificial heart) and soft robots. Other projects include the development of bio-inspired self-defending materials and sustainable air purification techniques.

Safe Drinking Water

Access to safe and clean drinking water remains a global problem, as 785 million people still lack improved drinking water sources (WHO, 2019). We investigate a novel approach to allow distribution of water filters to rural areas in developing countries by local manufacturing.

FML spin-off: external page Openversum