Oxygen concentrator

Further Reading

- Publication describing the Oxygen Concentrator in Detail: Knowledge Transfer in Support of the Development of Oxygen Concentrators in Emergency Settings During the COVID-19 Pandemic - Download PDF (PDF, 2.8 MB)

- Supporting Information

- Manual – DIY Oxygen Concentrator - Download PDF (PDF, 1.1 MB)

- Report – Optimization of an Oxygen Concentrator via Parameter Manipulation - Download PDF (PDF, 210 KB)

- Manual – DIY Oxygen Concentrator - Download PDF (PDF, 1.1 MB)

- Youtube Channel of Project Oxygenator - external page Link

The need for oxygen generators

Pneumonia is an inflammatory condition of the lungs. Treatment for pneumonia includes antibiotics, rest, fluids, management of complications and professional home care. Oxygen supplementation is one way to help patients who cannot breathe adequately on their own, where oxygenators are used to concentrate oxygen from ambient air to supply to the patient.

We propose a short-term solution to temporarily replace medical respirators by giving DIY instructions on how to construct an oxygen concentrator with minimal technical requirements. Our solution differs in technical complexity and performance and should be seen as an open-source resource, and may be used in combination with other projects.

The Coronavirus emergency

With the emergence of the corona virus, oxygen generators are required more than ever in the treatment of patients, where oxygen therapy is recommended by the World Health Organization (WHO). The handbook of COVID-19 Prevention and Treatment (The First Affiliated Hospital, Zhejiang University School of Medicine) recommends “oxygen therapy as soon as possible”, so any oxygen generator added to a COVID-19 treatment setting allows an earlier oxygen therapy for patients and prevents the selective application of oxygen therapy for patients with good prognosis. Consequently, we were set to come up with plans to construct oxygen generators in relatively simple environments using common materials.

Disclaimer

The information on this site is for educative and engineering know-how transfer purposes only. Please take appropriate safety precautions prior to attempting to replicate the systems. We do not guarantee any specifications for the devices and do not give any recommended use. Local rules and regulations will apply.

Method choice

There are several technologies available for generating air enriched in oxygen, including air separation by fractional distillation, electrolysis, and pressure swing adsorption. From these methods pressure swing adsorption has the lowest infrastructure cost and complexity and was selected for the generation of oxygen in a patient care scenario.

Pressure Swing Adsorption

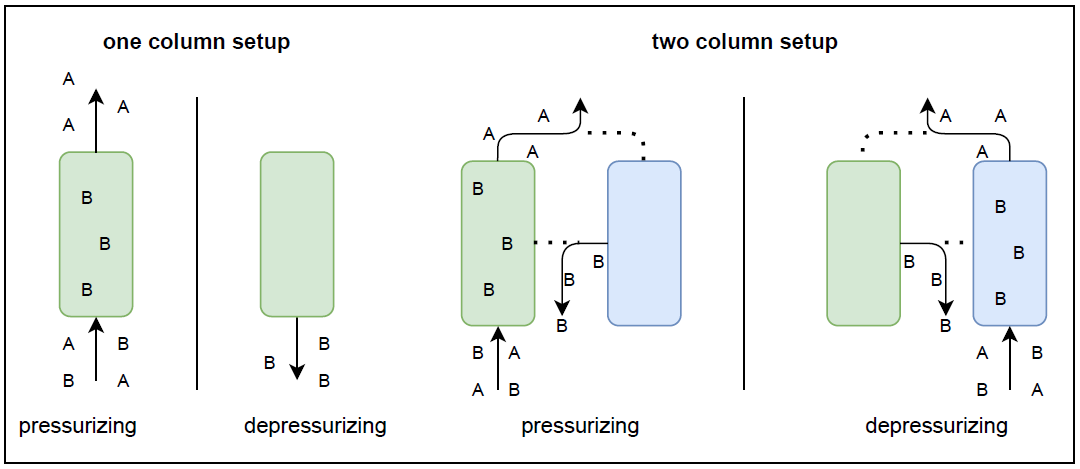

In Pressure Swing Adsorption (PSA), pressurised air is fed to a column loaded with zeolite. The Zeolite is a microporous material, which selectively captures the nitrogen from the airstream and oxygen enriched air leaves the column. As soon as the Zeolite is saturated with nitrogen, the column is vented to release the nitrogen. Then the column is ready for a second cycle, and in switched (loading/venting) operation can produce a quasi-continuous stream of oxygen enriched air.

The technology does not consume any material (other than air) and has a low energy demand (pressurised air (ca. 6 bar) and electricity to switch valves).

Depending on operation mode, system size and zeolite choice, Pressure Swing Adsorption is capable of generating oxygen enriched air with oxygen contents higher than 90% and with flow rates exceeding 10 l / min.

Applicability

The oxygen generator instructions given on this site are the work of a group of engineers to enable the access to oxygen enriched air to as many people and hospital care scenarios as possible. We do not sell or commercially manufacture any devices. We only offer education and know-how via this site and instructional videos. Additionally, we cannot give any guarantee that a device built by someone else will work or work to a given performance.

Safety and potential hazards

This technology uses pressurised air (up to 6 bar), which can be hazardous if using large containers. If using oil-free and toxin free parts and units for the construction of the concentrator, the oxygen enriched air leaving the unit will have the same purity (oil/toxins) as the air fed to the concentrator but will be enriched in oxygen and depleted in nitrogen and water. It might further be contaminated with dust originating from the Zeolites, and consequently dust filtration and re-humidification are required steps prior to any use of the oxygen enriched air stream.

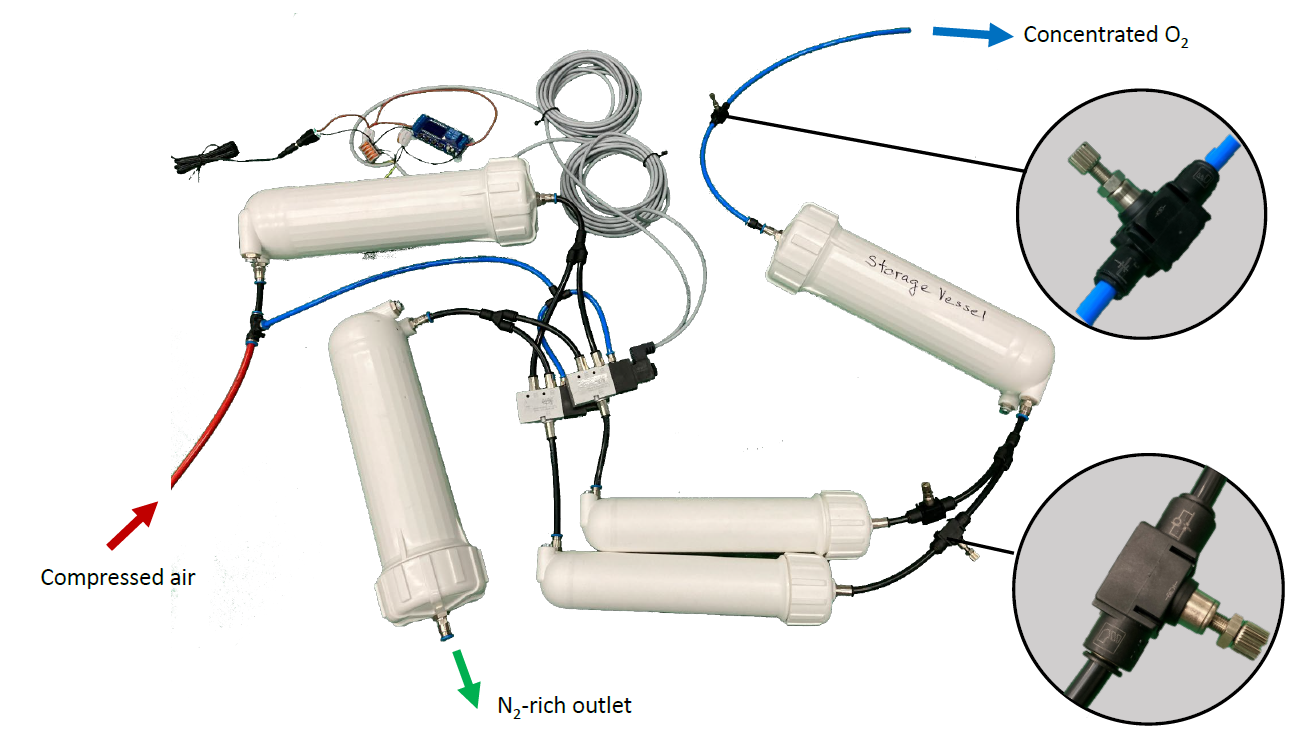

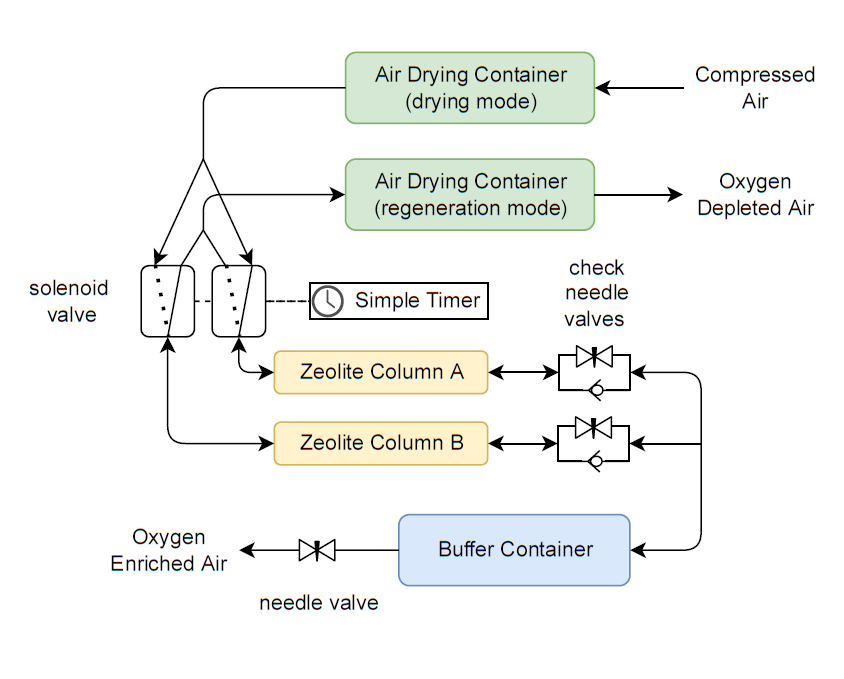

Compressed air is pumped into the system, where it is dried in a container filled with silica gel. Through a solenoid valve controlled by a timer, the dry air enters one of the two zeolite columns. The zeolite traps the nitrogen and lets the oxygen pass, resulting in oxygen enriched air. The oxygen reaches a buffer tank via a check needle valve, which does not let much oxygen leave the buffer when the column is depressurized, and nitrogen leaves the system through the other drying container. That bit of oxygen, however, is responsible to clean the column from any remaining nitrogen. The dry nitrogen passing through the drying container restores the silica gel by taking up the humidity, making it reusable. A constant oxygen stream can be then accessed from the buffer tank through a needle valve. Additionally, allowing the second column to fill with air, while the other is depressurising, make the process quasi-continuous.

To facilitate the construction of your own oxygenator we created a document further explaining the process, functioning and setup of the concentrator: (link to pdf coming soon).

Although the oxygenator is working well now, finding the right adjustments, and tweaking all settings was time consuming but must be done nonetheless to assure optimal results. In order to do so, we carried out many sets of experiments and analysed the flowrates and oxygen concentration to determine the best settings for our oxygenator. A detailed report on the results, their discussion and the execution of the experiments can be found here (link to pdf coming soon), to simplify the optimization of your own oxygenator.

Additionally, we have posted a series of short videos guiding you through our development process and construction. You can check it out here (external page YouTube).

Since we started this project in 2020, some time has passed and we are proud to have been able to help people around the world with our prototypes, which in turn helped us optimize the oxygenator and better understand the main concerns surrounding the device. To cover the most commonly asked questions, we created a Q&A, which provides a quick help in case of any doubts.

external page

Judging by the responses to our project, we realized that there are many people and institutions interested in DIY oxygen concentration. After months of working on improving prototypes, we had shifted our focus towards community building and have now collaborated with people and groups all over the world.